MK体育(中国)国际平台

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

MK体育(中国)国际平台

Jiangsu Shengli Centrifuge Manufacturing Co., Ltd.

Work hard and be honest

Automatic discharge centrifuge/Gypsum calcium centrifuge

PRODUCTS

PRODUCTS

Shengli Centrifuge Manufacturing

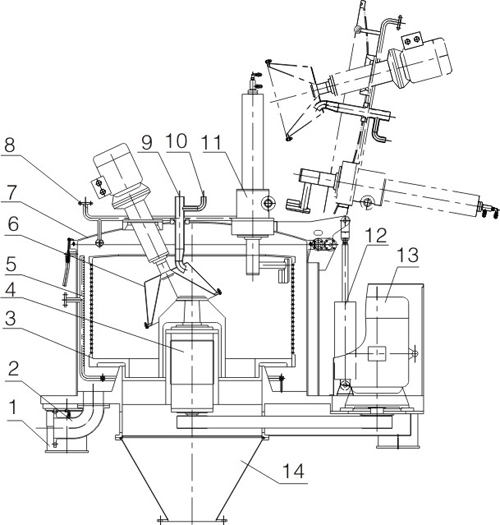

LGZ flat plate scraper discharge automatic centrifuge

Main features

◆Using PLC control, program setting, no one care of automation, early feeding, filtering, washing, filtering, discharging process monitoring.

◆Frequency control of motor speed, stable starting, adjustable separation factor.

◆Friction braking energy, non-contact braking, no dust pollution.

◆Fully closed structure, sealers adopt silicon rubber, or fluorine rubber, centrifuge lumen nitrogen protection, which can realize airtight explosion-proof requirements.

◆Reasonable structure design, online cleaning system (sprinkler system), to ensure the cleanliness requirements, accord with G M P specification.

◆Automatic movement components adopt pneumatic system, clean sanitation.

◆Material layer controller.

◆Optional gas auxiliary scraper, no residual after discharge in the drum filter cake.

◆Without the base installation, compact structure, beautiful appearance, convenient cleaning.

◆Damping vibration isolation system design scientific and reasonable, and USES the balance blocks and import high precision liquid damping agent type vibration isolator, all absorbed by the vibration isolation system equipment vibration, vibration based on the ground and surrounding environment without interference.

◆Equipment foundation balance board and can be used as operation platform, operation and maintenance more convenient.

◆Safety protection: speed testing, vibration protection, open cover protection, motor overload overheat protection, scraper rotating, lifting machinery electrical dual control, scraper and the linkage of the drum locking.

Optional configurations

◆Cleaning spray system; Nitrogen protection system; Material layer controller;

◆PLC program control; The hydraulic system;

◆According to the requirements of anti-corrosion of the user's separation material choose corresponding material (SUS304, 316, 316 l, 316, titanium, hartz alloy, plastic, rubber lining, spraying halar, etc.).

Main technical parameters

| Item | Model | ||||||

| LGZ800 | LGZ1000 | LGZ1250 | LGZ1360 | LGZ1500 | LGZ1600 | ||

| Drum diameter(mm) | 800 | 1000 | 1250 | 1360 | 1500 | 1600 | |

| Drum working highly(mm) | 400 | 450 | 630 | 800 | 800 | 750 | 800/1000 |

| Drum working volume(L) | 100 | 160 | 354 | 450 | 530 | 612 | 775/970 |

| Maximum loading limit(kg) | 140 | 215 | 480 | 580 | 680 | 825 | 1150/1300 |

| Durm speed(r/min) | 1200/1500 | 1000/1200 | 1000/1200 | 1000 | 970 | 850 | 800 |

| Filtration area (m2) | 1.0 | 1.41 | 2.47 | 3.14 | 3.41 | 3.53 | 4.01/5.02 |

| Separation factor (ω2r/ ɡ) | 645/1006 | 560/804 | 700/1006 | 700 | 715 | 606 | 573 |

| Motor power(kw) | 7.5/11 | 11/15 | 22/30 | 30 | 30 | 37 | 37/45 |

| Overall weight(kg) | 2000 | 2600 | 4200 | 4500 | 4700 | 8000 | 9500/10000 |

| Physical size(mm) | 1800×1300×2000 | 1950×1600×2100 | 2300×1800×2400/2700 | 2350×1900×2700 | 2800×2100×2700 | 2980×2250×3000/3200 | |

结构示意图

| 1.Damping absorber | 2.Outlet pipe |

| 3.Drum | 4.Drive assembly |

| 5.Bottom on-line cleaning | 6.Tilting tray distributing device |

| 7.Cover | 8.Top on-line cleaning |

| 9.Feed pipe | 10.Cleaning pipe |

| 11.Scraper assembly | 12.Cover oil cylinder |

| 13.Main motor | 14.Outlet hopper |

HOME | ABOUT US | PRODUCTS | NEWS | SERVICE | FACTORY | HONORS | ORDER | CONTACT | 中文版

Copyright(C)2021, Jiangsu Shengli Centrifuge Manufacturing Co., Ltd. All Rights Reserved. Supported by ChinaChemNet ChemNet Toocle Copyright Notice 备案序号:苏ICP备16066832号